System

Implementation

Low-cost modular infrastructure

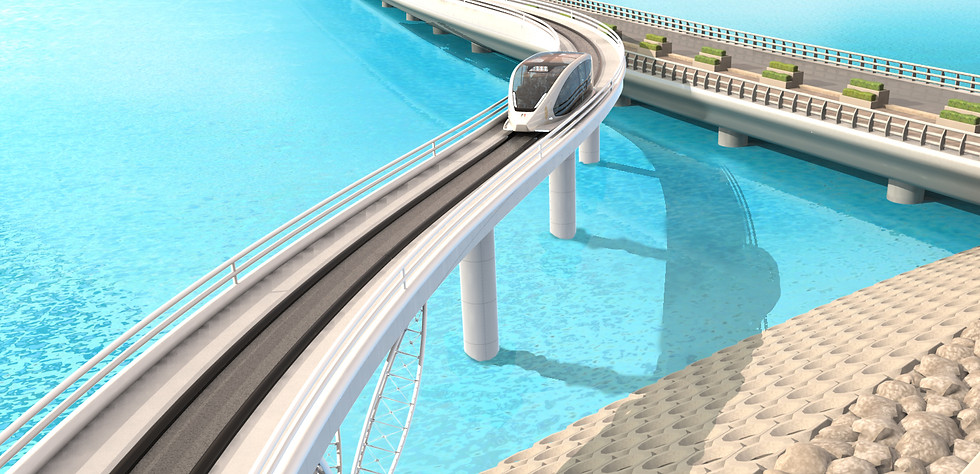

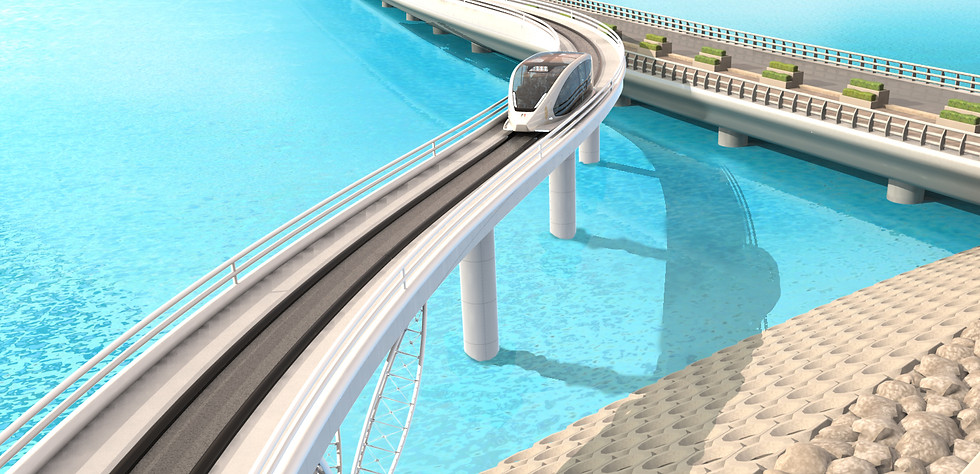

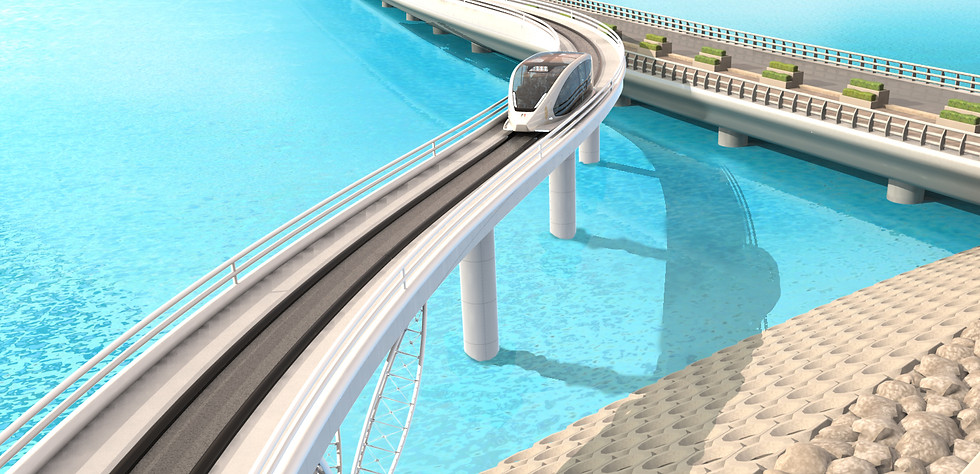

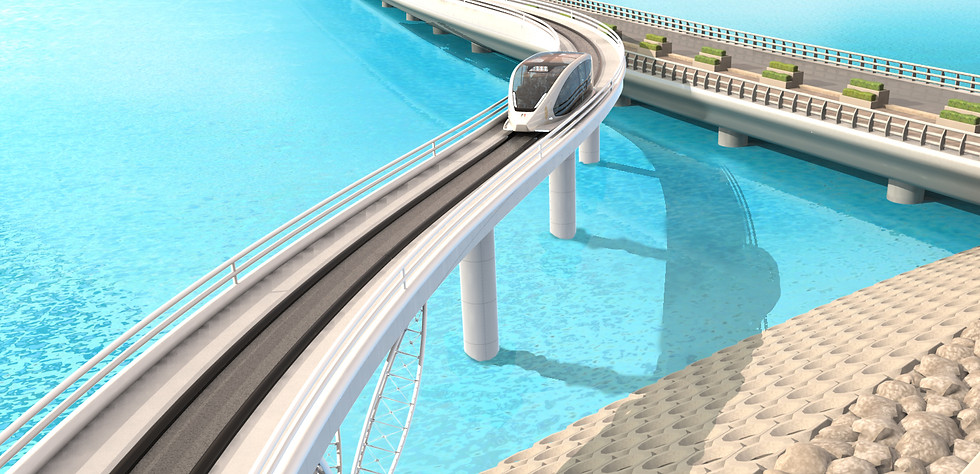

Instead of building one high cost line Magnovate networks utilize many low cost connections throughout a region - vastly broadening the market and improving accessibility. The narrow footprint of the guideway facilitates compatibility with existing rights-of-way, greatly expanding potential route options and avoiding costly property acquisitions that are required to accommodate traditional rail corridors.

Magnovate's Modular Construction Advantage

Building with modular precast elevated guideways offers significant advantages relative to conventional rail systems which are typically installed at-grade due to the tremendous cost of supporting heavy trains.

Modular construction advantages include:

-

Low-cost repetitious mass-production

-

60% less construction time

-

Predictable budgets and schedules

-

Durability and low maintenance

-

Minimizes environmental impact

-

90% less footprint than at-grade rail

-

Flexible and nimble alignment options

Automated Microtunneling

For projects that require tunneling, Magnovate’s smaller vehicle size allows the use of four meter diameter Micro Tunnel Boring machines (TBMs), typically used for water and utility tunnels, to excavate underground networks. The diameter of standard TBMs ranges from five to 17 meters.

By reducing the diameter of the tunnel, underground Magnovate networks can be excavated faster and more economically than traditional underground rail systems. Microtunneling achieves faster tunneling speeds by utilizing automation and continuous mining. For large underground networks, project schedules can be dramatically accelerated by deploying fleets of micro TBMs that tunnel towards each another using a meet in the middle approach.

Pre-cast Modular Guideways

Lightweight vehicles allow systems to be built using low-cost, lightweight guideways, that can be installed quickly and cheaply. They can be built elevated, at-grade, or below grade. The slender profile and flexibility of the guideways enable aesthetically-pleasing designs, as well as offering a broad range of customization options to blend in with the surrounding environment and to suit the practical needs of the systems application.

Owing to electrically powered vehicles and lightweight nimble infrastructure, economical station construction can be achieved by incorporating their design into existing or planned buildings. Stations can be located on elevated platforms, at-grade, or underground. The high degree of design flexibility offered by Magnovate’s nimble footprint provides planners with more options to place stations within Transit Oriented Developments or at Smart Mobility Hubs to facilitate seamless last mile connections.

Magnovate Stations